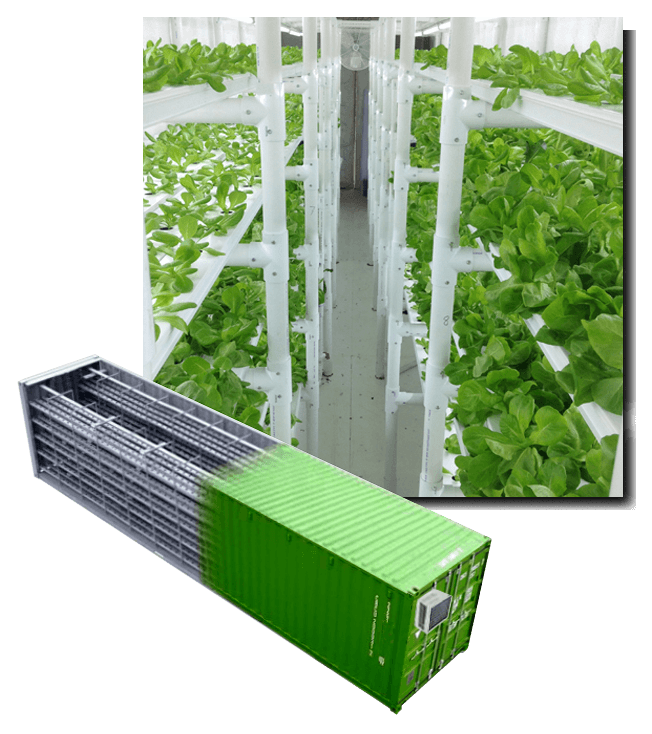

Container plant factory

The container plant factory is designed and manufactured on the basis of 40-foot-high refrigerated containers with good thermal insulation.The external size: 12191mm (length) ×2438mm (width) ×2896mm (height); the internal size: 11585mm (length) ×2290mm (width) ×2544mm (height).Our container plant plant is a closed planting system that enables farmers (agricultural technicians) to achieve stable vegetable production throughout the year.

Because containers can be transported freely, the distance from picking to the eating plants is shortened. Shorter transportation distances offer many benefits, such as fresher products, lower transportation costs, less waste, and less land for planting.

Container box system:

1.The container is the most commonly used 40 foot HC standard steel refrigerated container with high strength, good appearance, and durability, easy to repair. In accordance with ISO standards, suitable for sea transportation and inland transportation. The structural features are as follows: corten weather resistant steel frame, MGSS stainless steel outer plate, HGSs stainless steel inner and door lining, aluminum plate pre-coated inner top; double open back door, without rivet door plate.

2.Outer size:12192*2438*2896mm,Inter size:11590*2294*2674mm.

3.The self weight of the container is 3850kg, and the maximum weight (including equipment and facilities) is 5000kg.

4.

Seedling box and operation room are separated from growth room by aluminum alloy partition.

Seedling box and operation room are separated from growth room by aluminum alloy partition.

5.The seedling box is composed of four layers of a movable seedling tray, four layers of growth lamp, a water pump, a water tank, and a tool box. Each seedling tray length 1700mm 600mm wide, a total of 4 layers, can raise 6000 seedlings at the same time.

6.The area of operation room is 4 ㎡.

7.Tere are 10 layers of planting tray in the growing room. Each layer of the planting tray has an independent water supply switch and drainage pipe. Each planting tray is 1000 cm long and 70 cm wide. Used all the trays can plant 4800 lettuce at the same time.

8.All stainless steel in the container is food grade 304 stainless steel.

Water and fertilizer system:

1.The water and fertilizer system is a special system for NFT hydroponics planting, which has 4 ways of fertilizer suction channels and PLC control peristaltic pump for fertilizer suction. Each fertilizer suction channel is equipped with a 10L fertilizer barrel.

2.There are two 10 meter long water tanks under the growth frame, with a total storage capacity of 2600kg.

3.There is one 12000l / h water pump, one standby water pump, one pipeline UV disinfection lamp, and one oxygen filling device in the water tank.

4.The water tank is equipped with a water level switch, which can prevent the overflow of water and fertilizer. The circulating water and fertilizer return to the water tank through the return water filter.

5.The circulating solution in the water tank is sterilized by the pipeline UV disinfection lamp, and the water and fertilizer solution is oxygenated by the oxygen filling device and then circulates through the water pump to the planting tray.

6.There is one standby pump in the water tank. When the main water pump fails, the standby water pump can be started to supply water through the control panel.

Light source control system:

1.On the top of each planting tray, there are 10 LED plant growth lamps with 5 meters/branch, and the total length of the growth chamber LED lamp is 500 meters, and the total power is 6000W.

2.The LED growth lamp made of Japanese lamp beads, combined with our company's original water-cooling method, has extended the service life of the growth lamp.

3.The switch of each growth lamp can be controlled independently, and manual control and automatic control can be switched freely.

4.The main control system can automatically control the start time of LED lights, simulate sunrise and sunset.

5.The growth lamp in the seedling box can be controlled separately, and manual control and automatic control can be switched freely.

6.The operation room and growth room are equipped with lighting lamps.

Air circulation system:

1 .

. The air circulation system includes: 2 inlet fans, 2 outlet fans, 2 top circulation fans, 30 cross flow fans, 1 air conditioner and 1 dehumidifier.

The air circulation system includes: 2 inlet fans, 2 outlet fans, 2 top circulation fans, 30 cross flow fans, 1 air conditioner and 1 dehumidifier.

2. The air in the container can be changed automatically within 30 minutes through the main control system.

3. When the external temperature of the container is in the range of - 30 ℃ to + 40 ℃, the temperature of the growth chamber and operation room is in the range of 16-30 ℃.

4. The indoor temperature is uniform, the average temperature difference is within 1 ℃, and the temperature difference between day and night can be controlled between 6-10 ℃.

5.Equipped with an adjustable humidifier, combined with the main control system can make the humidity in the container constant, suitable for the uniform growth of plants.

6.If the concentration of CO2 exceeds the safe range, the air circulation system will change air automatically.

7.Air filter is optional equipment.

Intelligent control alarm system:

The intelligent control system specially developed for this product can automatically control all power equipment in the box. The human-machine interface adopts a touch LCD panel, which can display all parameters such as temperature, humidity, CO2, etc., and monitor the running state of the water pump, light source, and other systems.

1.The main control system can automatically control all kinds of environmental data such as light, temperature, humidity, and CO2 concentration through PLC, automatically control the NFT hydroponic planting system, automatically control the switching time of LED growth lamp, and simulate the natural environment.

2.The main control system can be accessed through the mobile app and browser.

3.It has its own network interface to upload and download work data in real-time, and the sensor data can be uploaded to the cloud platform in real-time. Users can view, download and print sensor data reports remotely.

4.With its own EC/PH sensor, it can collect the temperature, EC (electrical conductivity), PH and other data of water and fertilizer solution, and can calculate according to the data, and adjust the concentration and pH of fertilizer solution in real time.

5.Manual control and automatic control can be switched freely. It also has an emergency stop button to turn off the power supply in the container with one button.

6.The control panel is a 10-inch touch screen with an English interface or another language interface.

7.Alarm when the water level of the water tank is below the set value and notification to the app.

8.After the temperature in the box is set for 2 hours, the temperature is above or below the set range of 2 ℃, automatically adjust / alarm and notification to the app.

9.PH, EC, CO2, temperature, humidity beyond the set range, automatically adjust / alarm and notification to the app.

10.you can add a cloud camera to save the video file in the cloud for online viewing.

11.Ozone generator and intrusion alarm are optional equipment.

Product features:

1. Strong adaptability, not affected by temperature and humidity, altitude and adverse climate;

2. Modular design, high-strength box, convenient transportation;

3. Adopt automatic water and fertilizer circulation system to save manpower and realize intelligent production;

4. High strength, simple appearance, convenient maintenance, and low maintenance cost;

5. The artificial light source, only the spectrum which is beneficial to plant growth, does not need sunlight;

6.

Adopt patent LED light source recipe, ensure quality, save energy significantly;

Adopt patent LED light source recipe, ensure quality, save energy significantly;

7. Adopt environmental protection and energy-saving materials to realize high efficiency and stable production;

8. The container is clean and sealed, which can produce organic vegetables with zero pesticide residue without pesticide, so as to ensure food safety;

9. According to the different varieties, different growth models can be used to realize the foolishness of agricultural production;

10. Removable planting frame, according to plant size, from low to high free layout, free design;

11. Multiple containers are stacked, one is used for seedling raising, the other is used for planting , assembly line operation;

12.Combine small seeder and automatic packing machine to improve efficiency and form large-scale farm;

13.Customized design can be carried out according to customer needs and uses, such as grass, sprouts, seedlings, Chinese herbal medicine planting, primary and secondary school practice, and other special uses.

points for attention:

1. The access voltage is 380V and the maximum current is less than 40A. The IP protection grade conforms to the IP26 standard and the leakage protector 30mA.

2. The container is equipped with the user manual, circuit diagram, air circulation diagram, recommended standby list, maintenance schedule, 12-month warranty, 7*24-hour online service.

3. There are soilLess cultivation laboratory and special agronomist in the factory, providing technical support free of charge.

4. After the customer pays the deposit, he/she can provide online or offline operation training services free of charge and provide the recipe free of charge.

5.The company provides organic fertilizer, foliar fertilizer, seeds, farm tools, and other products for customers.

the plant factory can realize a variety of high-end soilless cultivation modes such as hydroponics/substrate cultivation/aerosol cultivation. Generally speaking, leafy vegetables are more economical to produce in plant factories. Because the production cycle of leafy vegetables is short, the turnover rate is fast, the price is high, and it is also more advantageous to eat all but root.

It is very advantageous to use container plant factories to grow flowers or other valuable medicinal materials. Planting in the box can promote the healing of grafted seedlings, adjust the florescence and so on.

In countries where cannabis cultivation is legalized, such as Canada / the United States, it is also a good choice to grow cannabis in container plant factories.

In the plant factory system, we have achieved the rapid, efficient and stable growth of more than a dozen kinds of vegetables, such as lettuce and herbs. You can also grow other fruits, vegetables, and medicinal plants.

the plant factory can provide stable vegetable supply for ocean freighters, border posts, islands and reefs, naval ships and other long-term closed sites every year; it can be used for special purposes such as plant technology publicity, visit and promotion base, primary and secondary school practice, etc.

Using this method to produce fruits and vegetables, the cost per kilogram is only 0.6-1 yuan (electricity, water, labor, nutrient solution), and it is also suitable for assembly line process operation. It can combine small seeder and automatic packaging machine to improve efficiency and produce better fruits and vegetables products than greenhouse planting. Container vegetable factory is more suitable for large-scale promotion of investors. It is a practical new model of plant factory, which can be widely used in agricultural transformation and upgrading, and will make a great contribution to China's vegetable basket project.